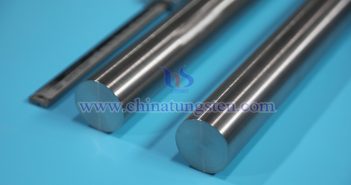

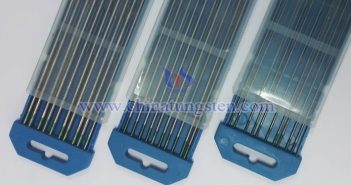

Metal tungsten, due to its high melting point, strong electron emission capability, and low vapor pressure, has become the preferred choice for thermionic emission materials. However, its high electron work function, elevated electrode tip temperature, and tendency for grain growth lead to unstable arc beams, difficult arc initiation, and a short service life in pure tungsten electrodes, limiting their use to alternating current welding. To overcome these drawbacks, manufacturers often add rare earth oxides with low electron work functions, such…