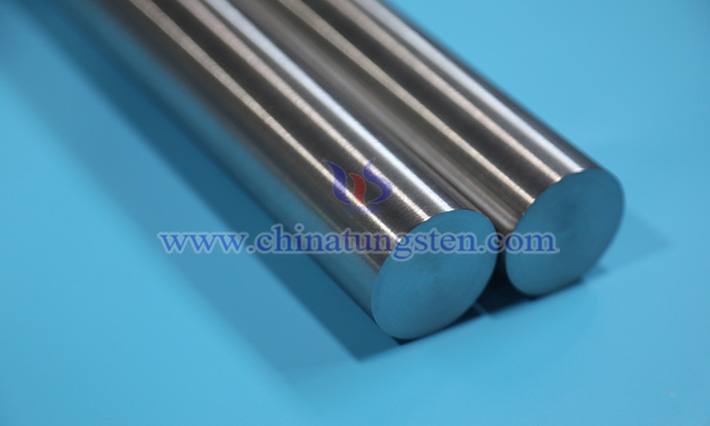

Mentioning tungsten alloy bar often conjures images of heavy industrial equipment or cold mechanical parts. However, this material, formed by fusing tungsten with other metal elements, harbors many "hidden talents" that defy conventional understanding. Its presence has quietly permeated fields ranging from deep-sea exploration to precision instruments, serving as an unsung hero behind technological breakthroughs.

I. The "Genetic Code" of Tungsten Alloy Bar

The unique performance of tungsten alloy bars stems from their meticulously designed composition ratios. Unlike simple material blends, the combination of tungsten with elements like cobalt and molybdenum follows specific proportions—typically with tungsten content exceeding 85%, and the remaining metals adjusted according to application needs. This ratio is the result of extensive experimental validation: tungsten’s high hardness requires other metals to offset its brittleness, while adding cobalt enhances wear resistance, and molybdenum improves high-temperature stability.

From a microscopic perspective, the grain distribution in tungsten alloy bars resembles a carefully orchestrated "array." Under an electron microscope, tungsten grains are seen tightly enveloped by a "binder" formed by metal elements, enabling the material to combine tungsten’s hardness with the toughness of other metals.

II. Performance That Defies Conventional Wisdom

In extreme environments, tungsten alloy bars perform exceptionally well. Whether temperatures rise abruptly from low to high, their dimensional stability remains relatively good. This means they can withstand the intense heat of a spacecraft re-entering the atmosphere while maintaining structural integrity in low-temperature conditions.

When subjected to non-uniform impact, tungsten alloy bars exhibit significant resistance to deformation, a property that plays a critical role in applications like bulletproof armor and high-speed mechanical clutches.

In special media, their adaptability stands out. Even when exposed to high-concentration strong acids for extended periods, the surface corrosion is minimal; even in the radiation environment of a nuclear reactor, the degradation of their mechanical properties is effectively controlled.

III. "Differentiated Competition" with Other Alloys

Compared to lead alloys, tungsten alloy bars offer a clear environmental advantage. While both have high densities, lead releases toxic substances at high temperatures and pollutes the environment when discarded, whereas tungsten alloy is non-toxic, non-radioactive, and recyclable. This characteristic has led to tungsten alloy gradually replacing lead as the preferred material for new radiation shielding in medical applications.

Relative to high-carbon steel, tungsten alloy bars excel in high-temperature resistance and wear resistance. High-carbon steel’s hardness significantly decreases at elevated temperatures, whereas tungsten alloy bars maintain good hardness even in more extreme heat.

Compared to titanium alloys, tungsten alloy bars have more targeted competitive advantages. Although titanium alloys are renowned for their high strength and lightweight properties, their lower density limits their use in weight-dependent scenarios. Despite tungsten alloy’s greater processing difficulty compared to titanium alloy, its superior stability in high-temperature environments secures its importance in fields like aviation engines.

IV. "Technical Bottlenecks" and Breakthroughs in Processing

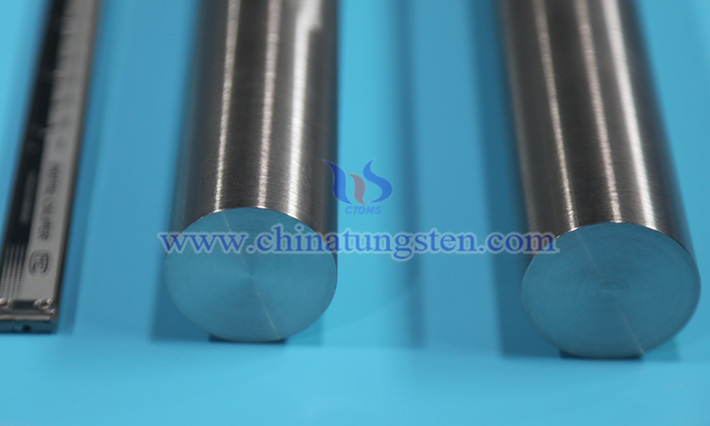

Powder metallurgy is the mainstream method for producing tungsten alloy bars, with the sintering stage demanding high technical precision. The sintering temperature must be controlled within a specific range; deviations can lead to coarse grains and increased material brittleness. Recently, the application of microwave sintering technology has overcome this challenge, using uniform heating to significantly improve the yield of finished products.

Breaking through the brittleness of tungsten alloy is central to plastic processing. Traditional cold working often causes cracking, but the emergence of the "warm rolling process" has marked a breakthrough—rolling at suitable temperatures preserves material hardness while enhancing plasticity, allowing tungsten alloy bars to be processed into thinner sheets, opening new possibilities in the precision electronics field.