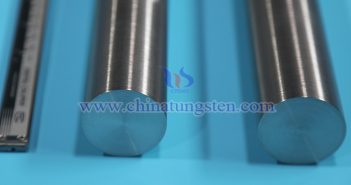

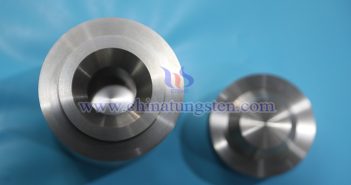

Tungsten alloy, with its comprehensive advantages in density, temperature resistance, and mechanical properties, serves as a bridge connecting traditional industry with high-end manufacturing. From aerospace to medical electronics, from defense security to new energy development, tungsten alloy is continuously expanding its application boundaries through innovations in materials science. The characteristics of tungsten alloy bars include high density, high melting point, high strength, good toughness, and more. High Density: The density of tungsten alloy bars typically ranges from 16.5 to 18.75…